Embodied Carbon in Civil Infrastructure and Why It Matters Now

Introduction

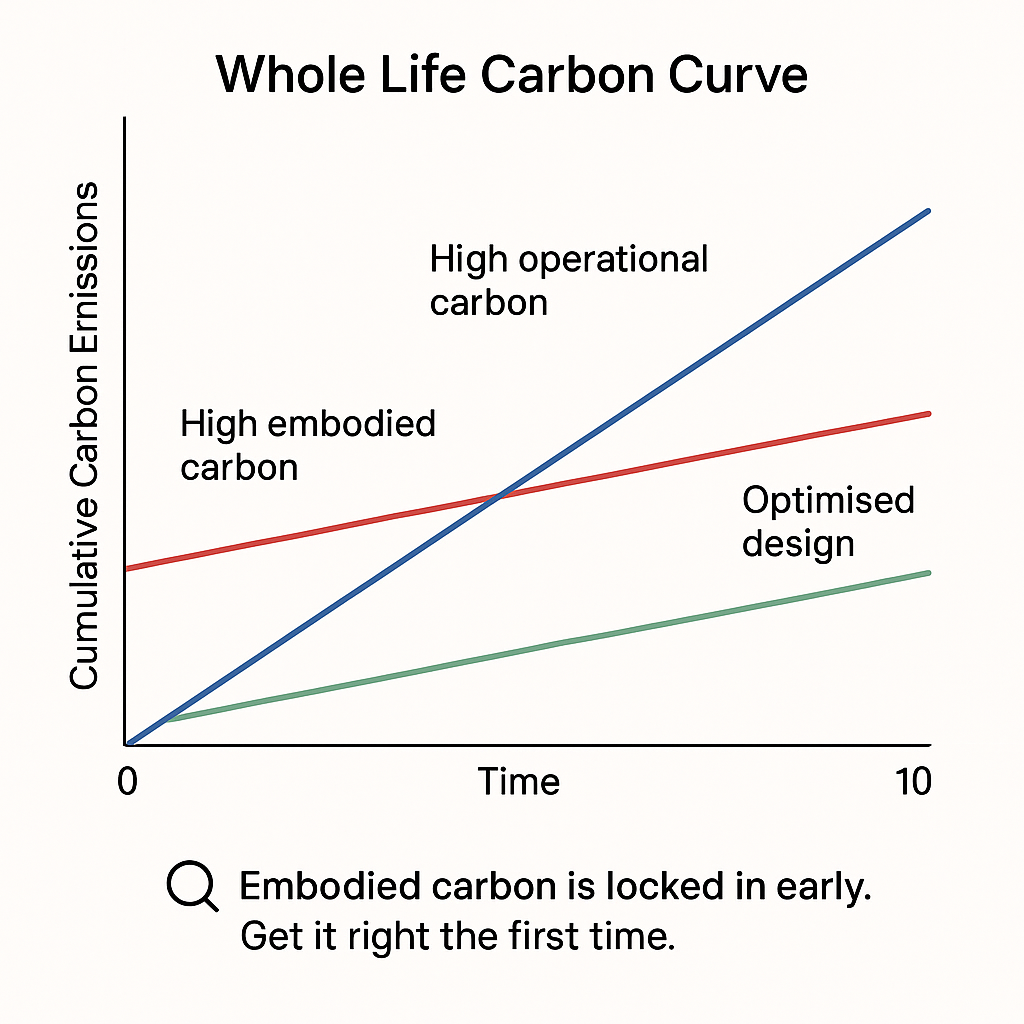

The way we talk about carbon in civil engineering is changing. It used to focus mainly on operational emissions, which are the carbon released during the use of a building or infrastructure. But that only tells part of the story and the focus is now shifting to embodied carbon, which covers everything that happens before and after an asset is in use. That includes material extraction, processing, manufacturing, transport, construction, maintenance, and eventually demolition and disposal.

As the industry moves towards net zero and more climate-conscious design, understanding embodied carbon has become a core part of the job. It is not just a nice extra or something for the sustainability team to worry about. This article explores what embodied carbon actually is, why it matters more than ever, and how engineers can start factoring it into everyday design choices.

What Is Embodied Carbon?

Embodied carbon is the total greenhouse gas emissions linked to the materials and processes involved in delivering a built asset, not including what happens during everyday use.

It covers:

Raw material extraction, such as limestone for cement or iron ore for steel

Manufacturing and fabrication

Transport to site

On-site construction activities

Ongoing maintenance and repair

Demolition, disposal, or reuse at the end of life

This is different from operational carbon, which comes from using the asset. That includes things like energy for lighting, heating, and cooling.

Why It Matters Now

There are three key reasons why embodied carbon is getting more attention across the industry:

1. Emissions happen early

In many civil engineering projects, most of the carbon is released before the asset is even in use. Roads, bridges, and large earthworks often have little or no operational energy demand. That means embodied carbon makes up most of their overall footprint.

2. The push for net zero

The UK has committed to reaching net zero by 2050. Every sector, including construction, has a role to play in cutting emissions. Tackling embodied carbon is a vital part of meeting those national targets.

3. Design decisions make a difference

Engineers and designers have real influence over carbon at the early stages of a project. Simple decisions can lead to big reductions, often without extra cost. For example, reusing site-won material, specifying low-carbon concrete, or trimming down material volumes can all make a measurable impact.

Lifecycle Thinking vs Design Life Thinking

Engineers have traditionally focused on "design life" - making sure a structure lasts for a set number of years. But that approach can often overlook the bigger picture as it does not consider the full carbon impact of a structure from start to finish.

Lifecycle Assessment, or LCA, takes a more complete view. It looks at carbon emissions across every stage of a project, from raw material extraction through to end-of-life. For example, a steel bridge designed for 120 years might end up with a lower total carbon footprint than a concrete one designed for 60 years, especially if the steel is recyclable and needs less maintenance over time.

Material Choices Make a Difference

Not all construction materials are created equal when it comes to carbon. The type of material you choose can have a massive impact on embodied emissions.

For example:

Concrete and cement are responsible for around 8 percent of global CO₂ emissions. Reducing the amount of cement used or swapping in supplementary materials like GGBS or fly ash can help cut that figure down.

Steel has a high embodied carbon footprint because of the energy used in production. However, it is widely recyclable. Choosing recycled steel or Electric Arc Furnace (EAF) steel can cut emissions by up to half.

Aggregates and fill can carry a big carbon cost, particularly from extraction and transport. Reusing site-won fill or selecting recycled aggregates can significantly reduce that impact

Practical Steps for Engineers

Civil engineers can have a real impact on carbon, not just in theory but in everyday decisions. Here are a few practical ways to reduce embodied carbon on real-world projects:

Use free tools and databases

Resources like the ICE Carbon Database and the LETI Embodied Carbon Primer are good starting points. They offer standard values that help you make informed design decisions.Make carbon part of optioneering

When weighing up different design options, bring carbon into the mix alongside cost and programme. It helps shift the conversation early and keeps carbon on the table.Question default specifications

Ask if you really need virgin aggregates. Suggest using low-cement concrete or designing leaner structural solutions. Challenge the norm when it makes sense to do so.Champion reuse and circularity

Look for ways to reuse materials, components, or even whole structures. It is not always straightforward, but it can lead to big carbon savings.Collaborate early

Work closely with contractors and suppliers to understand what low-carbon options are available and what the practical limits might be.

Case Examples

This is already happening across the UK. Real projects are finding smart ways to cut embodied carbon:

Urban drainage schemes have reused site-won clay as fill, avoiding the need to import or export material.

Sustainable highway projects have used foamed concrete with GGBS and recycled steel reinforcement.

Flood defence schemes have switched from concrete walls to earth bunds, reducing both carbon and cost.

These examples show that low-carbon design is not just an ideal. It is being delivered on site, often in ways that also save money and align with stakeholder goals.

Conclusion

Embodied carbon is becoming a core responsibility for civil engineers. It calls for a shift in mindset - moving beyond just meeting design life or compliance, and towards making decisions that reflect environmental value.

For early-career professionals, building carbon awareness into your design work can set you apart. It improves the quality of your engineering and shows leadership on sustainability.

Civil infrastructure has huge potential to lead the way on carbon reduction. As engineers, we are not just solving technical problems. We are also carbon accountants, value-driven designers, and stewards of the built environment for future generations.

References

HM Government (2020). The Ten Point Plan for a Green Industrial Revolution. Available at: https://www.gov.uk/government/publications/the-ten-point-plan-for-a-green-industrial-revolution

Chatham House (2018). Making Concrete Change: Innovation in Low-carbon Cement and Concrete. Available at: https://www.chathamhouse.org/2018/06/making-concrete-change

University of Bath (2019). Inventory of Carbon and Energy (ICE) Database v3.0. Available at: https://www.circularecology.com/embodied-carbon-footprint-database.html

LETI (2020). Embodied Carbon Primer. London Energy Transformation Initiative. Available at: https://www.leti.london/ecp

World Steel Association (2023). Steel's Contribution to a Low Carbon Future. Available at:https://www.worldsteel.org/en/dam/jcr:b1cbfe46-bd76-4b1b-bf12-c2e6c6f90832/Position_paper_climate_action.pdf